Environmental Management

Through the manufacture of steel tubes using iron, a highly-recyclable material, we endeavor to ensure a comfortable environment for the next generation.

With our basic philosophy of “co-existence and co-prosperity of the earth, nature and humanity,” we strive to provide a valuable link. To this end, we engage in the following activities.

We endeavor to prevent pollution, conserve resources and conserve energy, with consideration for their effect on the environment.

We engage in business activities in accordance with social norms, including laws and regulations related to the environment, and agreements with local residents.

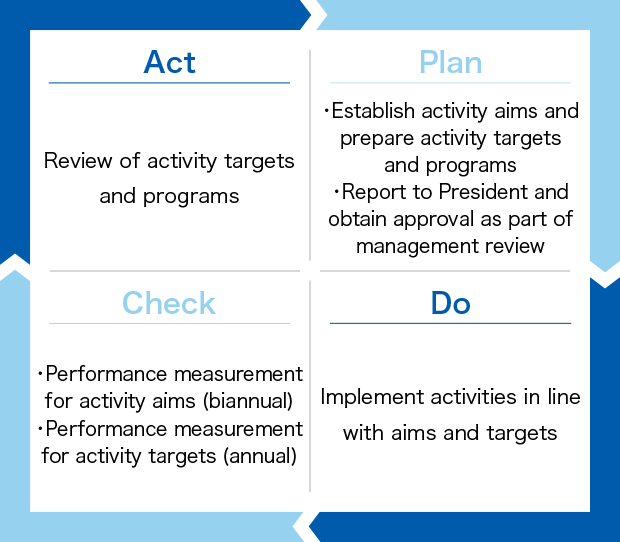

We establish aims and targets related to the environment, and engage in activities aimed at continual improvement, including environmental management systems. We review these regularly.

We disclose this policy internally and externally.

Externally: we publish it on our website, and disclose it in an appropriate manner when requested.

Internally: we disseminate it among all employees, and aim to heighten environmental consciousness.

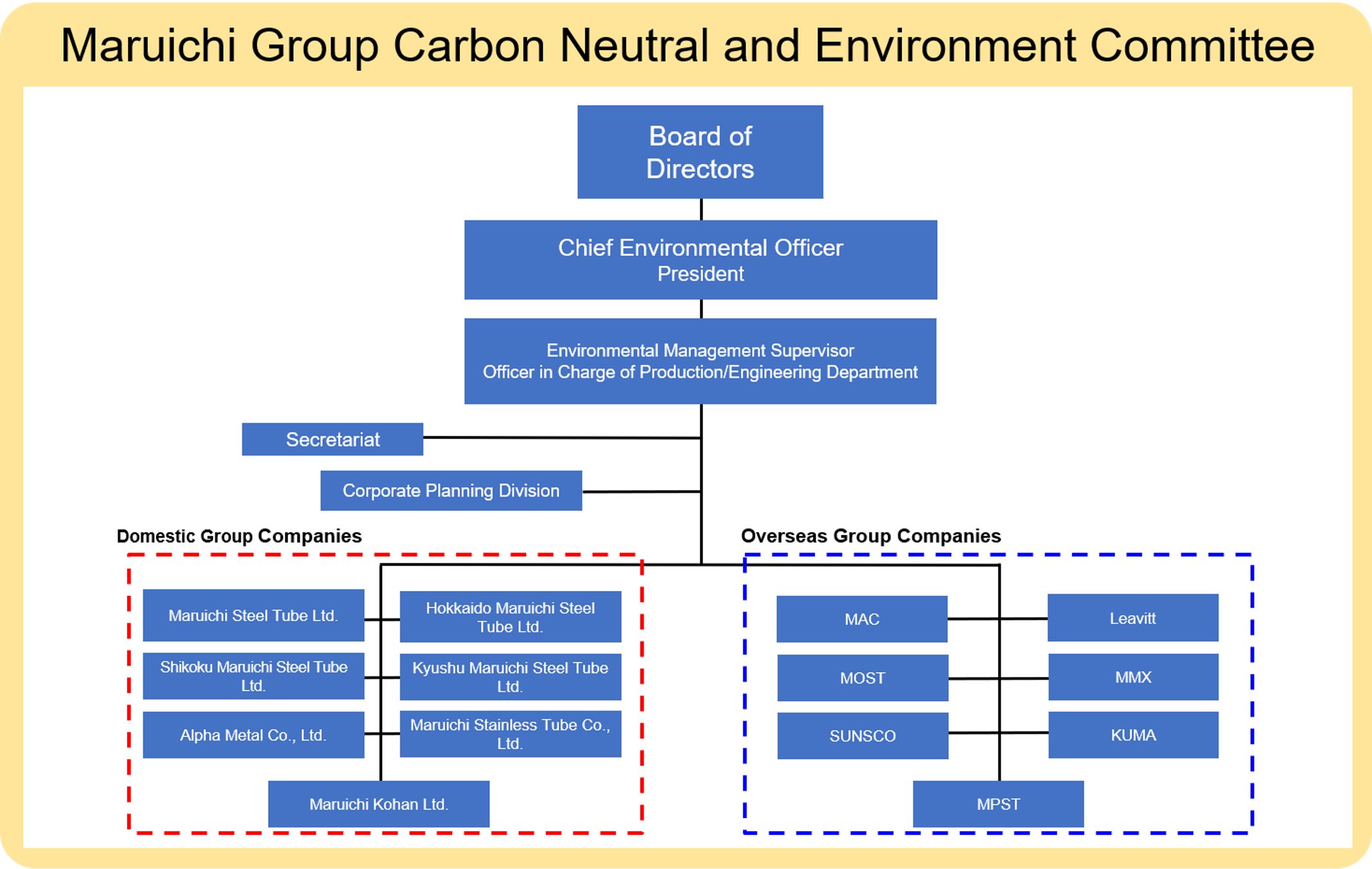

The Maruichi Steel Tube Group promotes environmentally-friendly business activities, and has established an environmental management system that incorporates the requirements of JIS Q 14001 (ISO 14001), in order to achieve sustainable development as a company trusted by society.

We have established an environmental management system that incorporates the requirements of JIS Q 14001 (ISO14001) through the PDCA cycle.

| Date of registration | August 8, 2003 |

|---|---|

| Date of renewal | January 16, 2024 |

| Certification body | JAB: Japan Accreditation Board |

| Review and registration body | JSA: Japanese Standards Association |

| Applicable standard | JIS Q 14001:2015, ISO 14001:2015 |

| Registration number | JSAE 699 |

| Scope of registration |

1)Design and manufacture of welded carbon steel pipe for industrial plant, general and mechanical structural applications, automotive/motorcycle parts, conduit and gas & water piping and steel pipe piles 2)Design and manufacture of MARUICHI POLE, steel tower and steel pole 3)Design and manufacture of pickled coil, cold reduction coil and galvanized coil(hot-dip zinc-coated steel coils and hot-dip 55% aluminium-zinc alloy-coated steel coils) 4)Design and, manufacture of steel sections for general structure |

| Registering organization | Maruichi Steel Tube Ltd. Sakai Plant, Tokyo Plant, Nagoya Plant, Takuma Plant, Sakai Pole Plant, Kashima Pole Plant, Hokkaido Maruichi Steel Tube LTD. (Tomakomai Plant), Shikoku Maruichi Steel Tube LTD. (Shikoku Plant, Tachibana Plant), Kyushu Maruichi Steel Tube LTD. (Kyushu Plant) |

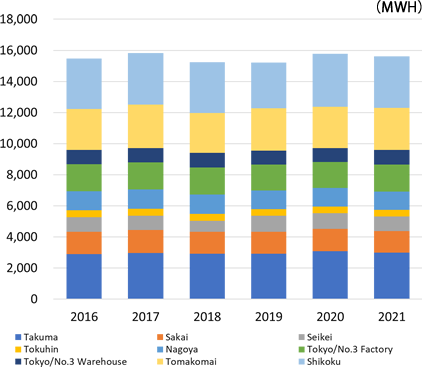

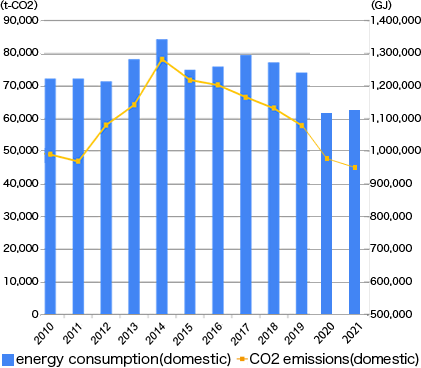

At the Maruichi Steel Tube Group, we are generating electricity from solar panels installed at seven plants across Japan, in order to contribute to bringing about a low-carbon society using renewable energy. We also implement various initiatives related to energy conservation, and share information within the Maruichi Steel Tube Group at monthly environmental meetings.

This data applies to the Maruichi Steel Tube Group in Japan, excluding Maruichi Kohan Ltd., Maruichi Stainless Tube Co., Ltd. and Alpha Metal Co., Ltd.

・Conversion from LPG to LNG at Takuma Plant

・Introduction of waste heat utilization equipment

・Adoption of inverter control to motors

・Adoption of energy saving equipment such as high-efficiency transformers and LEDs

A range of environmental laws and regulations apply to business activities. In addition to regular measurement of water discharge and noise at each of our production bases, we also conduct regular evaluation of compliance with these laws and regulations.

| Field | Applicable laws and regulations | |

|---|---|---|

| Land usage | Factory Location Act | |

| Global environment | Act on Rationalizing Energy Use, Act on the Improvement of Energy Consumption Performance of Buildings, Act on Promotion of Global Warming Countermeasures, Act on Rational Use and Appropriate Management of Fluorocarbons | |

| Pollution | Enhancement of pollution prevention systems |

Law on the Establishment of Organizations to Prevent Pollution at Specific Plants |

| Air pollution | Air Pollution Control Act, Law on Nitrogen Oxide and Particulate Matter in Automobile Exhaust | |

| Water pollution | Water Pollution Prevention Act, Water Supply Act, Sewerage Act, Septic Tanks Act | |

| Soil pollution | Soil Contamination Countermeasures Act | |

| Noise & vibration | Noise Regulation Act, Vibration Control Act | |

| Odors | Offensive Odor Control Act | |

| Toxic substances | Law concerning Pollutant Release and Transfer Register, Act on the Regulation of Manufacture and Evaluation of Chemical Substances, Poisonous and Deleterious Substances Control Act | |

| Waste | Waste Management and Public Cleansing Act, Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes, Act on Recycling, etc. of End-of-Life Vehicles, Act on Recycling of Specified Kinds of Home Appliances, Act on Recycling of Small Home Appliances, Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging | |

| Labor health and safety | Industrial Safety and Health Act, Fire Service Act, High Pressure Gas Safety Act | |

We apply coatings certified under “JIS K 5674 (lead-free, chromium-free anticorrosive paints) class 2” to steel tubes certified under “JIS G 3466 (carbon steel square and rectangular tubes for general structure).”

・We use high-performance coatings equivalent to water-based anticorrosive paint (JASS 18 M-111).

・Outstanding corrosion resistance through the application of JIS K 5621 (anticorrosive paints for general use) coatings. *

・We use highly anticorrosive water-based rust-proofing coatings that do not contain heavy metals such as lead or chromium.

・The formaldehyde diffusion level is F☆☆☆☆.

| JIS K 5621 (class 4) | JIS K 5674 (class 2) | |

|---|---|---|

| Cyclic corrosion resistance | No bulging, rusting or peeling after 20 cycles | No bulging, rusting or peeling after 36 cycles |

Red lead color

Gray

Note 1: The coating thickness of ordinary products does not conform to the requirements of the technical standards for constructing public buildings. Please specify if a conforming coating thickness is required.

Note 2: The sample colors differ in tone to actual colors used.

ALZ-55N Screw-less, thin steel Steel electrical conduits and normal bends

These environmentally-friendly pipes contain zero chromium.